Stand out from the rest

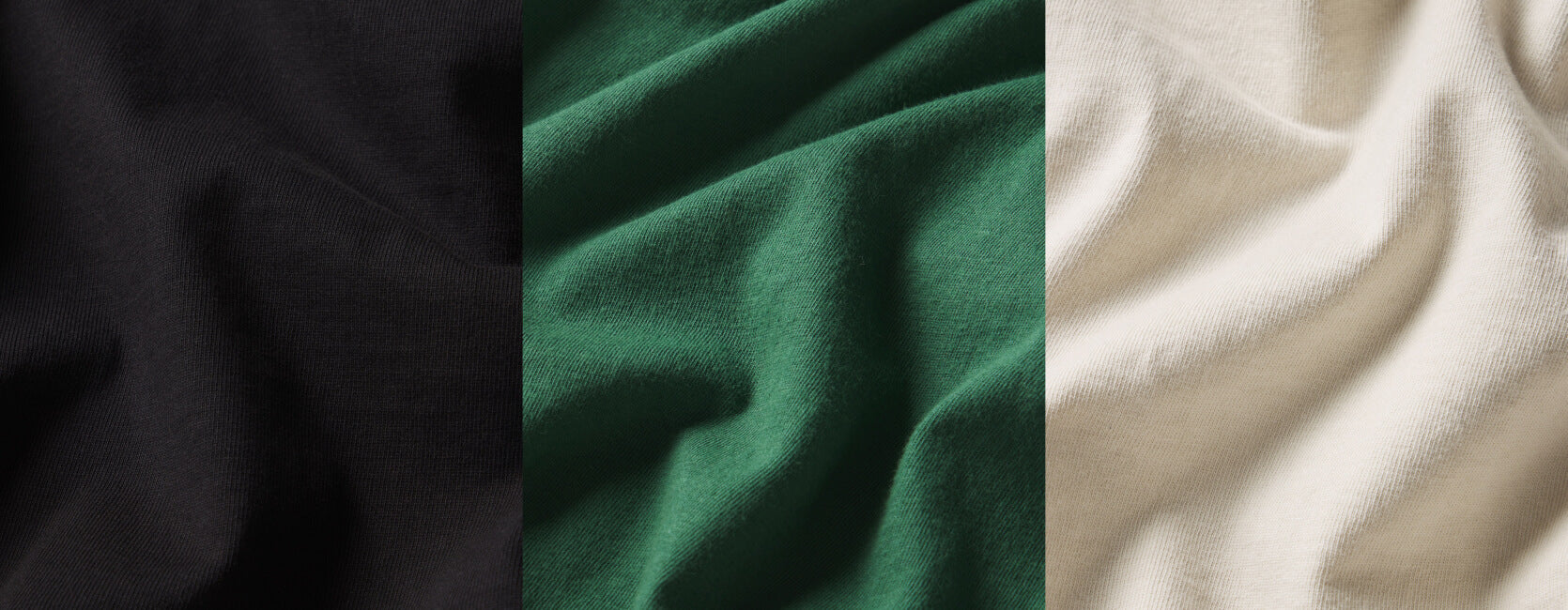

Expand your brand's potential beyond standard, pre-dyed products that don't align with your brand's vision. Our garment-dyed blanks are unrivaled by competitors.

Through a meticulous industrial process that includes laundering, dyeing, and the application of silicone softeners and enzymes, our garments attain unparalleled quality, resistant to the common wear-and-tear of home laundering.

This innovative method eradicates typical issues such as shrinkage, twisting, and color fading, resulting in a garment that not only meets but exceeds the longevity of traditional tees. With our products, experience enduring quality that

truly stands the test of time.

What makes garment dye so much better?

Our garment dye process represents a significant advancement in textile customization, offering a broad spectrum of color options to meet and expand upon your brand's visual narrative. It's an approach that not only diversifies your palette but also enhances the garment's lifecycle.

The issue of shrinkage is addressed head-on; we engineer garments that preserve their size and shape far beyond the first wear, ensuring a lasting fit that customers can rely on.

Durability is paramount—our garments are constructed to withstand repeated wear and washing.

Pigment dye is a unique coloration method that applies color to the surface of textiles, rather than saturating the fibers themselves. This creates a distinct look often desired for its vintage or weathered appearance. The process involves a pigment, which is insoluble in water, forming a film on the surface of the fabric. To ensure the pigment adheres properly and to improve its durability, a binder is used in the process, which essentially acts like glue to bind the color to the fabric. One of the characteristic features of pigment-dyed textiles is that they tend to gradually fade over time with washing, which contributes to their aesthetic appeal. This fading is not seen as a flaw but rather a desirable quality that adds character and a lived-in feel to the garment.

Discharge printing will not work on pigment dyes.

Reactive dyes are a type of dye that chemically bonds to the fabric, which makes the colors it produces very strong and vibrant. They're mostly used for coloring plant-based fabrics like our 100% cotton garments. The colors made by reactive dyes are bright and last a long time, even with lots of washing, which is why they're so popular for dyeing clothes and other items that get washed often.

Reactive dye is the best for printing and most embellishments.

Learn More

Garment dyeing is the process of coloring clothes after they're made, rather than dyeing the fabric beforehand. This method creates unique color variations and a softer texture, reduces shrinkage, and offers manufacturing efficiency and potential environmental benefits.

Our fabric undergoes a pre-laundering treatment before being cut and sewn, which then after we strictly avoid re-rolling. Our method involves flat-folding and handling the fabric with utmost care while it's still raw, ensuring it's spread out and allowed to relax to achieve the best results. After assembly, the garments are pre washed once more to remove any impurities that could affect the dyeing process and to release any tension introduced during sewing. The outcome is a garment impeccably pre-treated to be shrink-resistant, guaranteeing the size and shape you buy is what you keep, even after dyeing.

Our competitors are likely not implementing a comprehensive pre and post-assembly washing regimen, this leaves them at a higher risk of producing garments that shrink significantly or alter in shape after the consumer's first wash. This undermines the garment's quality and durability, disappointing customers and damaging brand reputation.